Appearance contrast

-Poor Quality Shocks:

- Use ordinary spray paint.

- The product is not beautiful

-KTT product:

Using automatic electrostatic spraying and electrophoretic paint, the product has a bright appearance, strong paint adhesion, water as a solvent, less waste and more environment friendly.

The product is beautiful and firm.

Welding process comparison

-Poor Quality Shocks:

- Manual welding;

- There are obvious nodules in the welding part, and the welding appearance is poor, unstable and prone to false welding.

- Weld two pieces, the welding scar is slightly rough, and the welding strength is low.

-KTT product:

- Fully automatic mechanical welding line

- The welding appearance is meticulous, the stability is high, the welding welding is reliable, and the virtual welding is avoided.

- 360° welding, the overall welding appearance is smooth, and the welding strength is reliable.

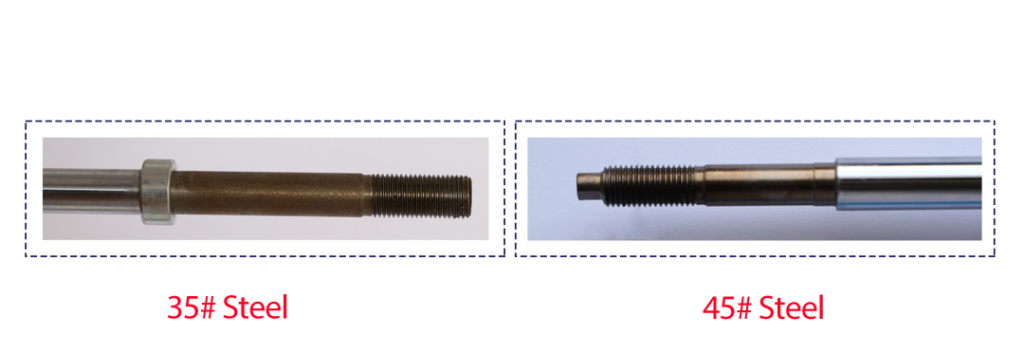

Piston Rod Comparison

-Poor Quality Shocks:

- Piston rod material: 35# steel

Material: low performance on strength, toughness, wear resistance and welding.

Performance: The sealing material of the piston and the working cylinder has a low finish, poor toughness, and is easy to stretch and deform, and the service life of the product is average (usually it starts to leak after a period of time) - No treatment on the head of the piston rod

-KTT product:

- Piston rod material: standard 45# steel material: better toughness, strength, wear resistance and welding performance

Performance: The piston structure ensures close contact between the piston and the working cylinder wall, eliminating oil leakage between them, so as to obtain a stable damping force, and the product has a longer service life (no oil leakage after long-term use) - Piston rod head treatment

The head of the piston rod is processed by dehydrogenation industry to solve the problems of steel stress and hydrogen embrittlement. The head is not easy to break during the installation and use of the shock absorber, and it is safe and reliable to use.

Valve parts

-Poor Quality Shocks:

Using the early process form, the performance of the elastic element will be attenuated after the product is used for a period of time, the damping force will be greatly changed, the service life is short, and the comfort is poor.

-KTT product:

Using the latest technological form, the damping force is adjusted by the liquid flow rate and the valve opening angle, which is more stable, more comfortable and prolongs the service life.

Oil Seal

-Poor Quality Shocks:

Using ordinary oil seals, the product has average performance for wear resistance and anti-aging properties.

-KTT product:

Imported high-quality oil seals are used to reduce the friction between the piston rod and the oil seal and prolong the life of the oil seal and the product. Effectively seal oil and high-pressure nitrogen, isolate external dust and dirt, and ensure product quality and life.

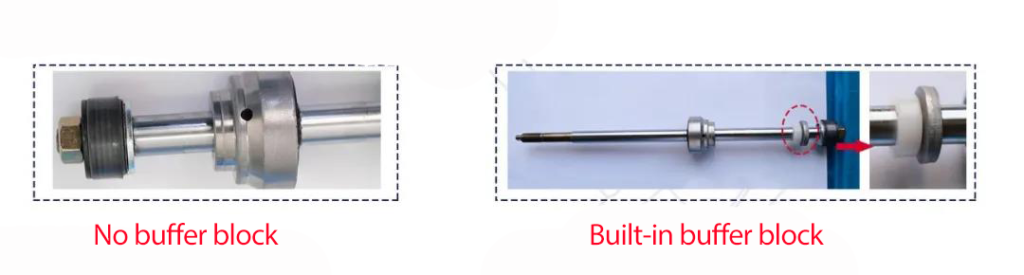

Other parts insides

-Poor Quality Shocks:

- No buffer block

- Performance: Prone to collision noise and pull off.

-KTT product:

- Built-in buffer block

- Performance: Eliminate the risk of product collision and pull-off.

Shock Absorber Oil

-Poor Quality Shocks:

- Ordinary shock absorber oil

- The shock absorber oil is turbid and contains impurities. 3. It is easy to produce bubbles at high speed and high temperature, which is unstable, has a short service life, and is prone to abnormal noise.

-KTT product:

- High-quality high-performance shock absorber oil, good anti-foaming and anti-shearing performance, reducing the product’s empty travel and the wear of internal valve parts, and long product life.

- The shock absorber has superior temperature/viscosity performance, suitable for normal use of vehicles in different regions and different climatic conditions, and has excellent high and low temperature resistance.